Oct 2025

Friction and Friction Coefficient

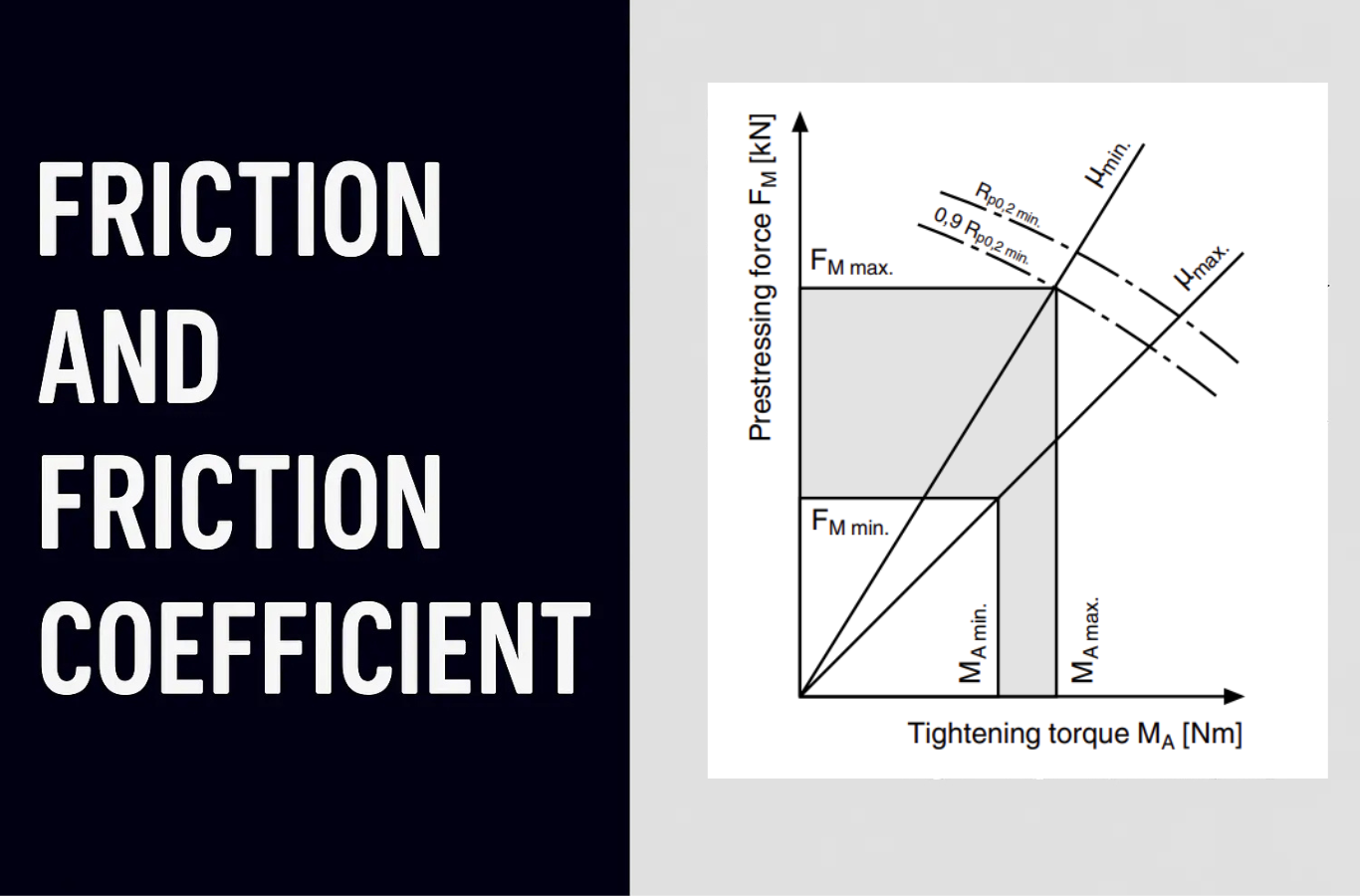

Friction plays an important role in how well screw connections stay tight and secure. The amount of friction, known as the friction coefficient, can change depending on the materials used, how smooth or rough the surfaces are, any coatings or treatments applied, and the type of lubrication used. These factors can make friction increase or decrease, so it’s important to keep the conditions as consistent as possible. If friction is too high or too low, the screw joint may not hold properly or could become damaged. By controlling surface finishes, using the right lubrication, and following proper tightening methods, we can make sure that screw connections remain strong, safe, and reliable.

| Friction coeff. class |

Range for µG and

µK

|

Typical examples for:

Material/surfaces |

Lubrication |

| A |

0.04–0.10 |

metallic, bright-polished

black tempered

phosphated

galvanized coatings such as Zn, Zn/Fe, Zn/Ni

zinc laminated coatings

|

solid lubricants such as MoS2, graphite, PTFE, PA, PE, PI in lubricating lacquers or in pastes

wax glazes

wax dispersions

|

| B |

0.08–0.16 |

metallic, bright-polished

black tempered

phosphated

galvanized coatings such as Zn, Zn/Fe, Zn/Ni

zinc laminated coatings

Al and Mg alloys

|

solid lubricants such as MoS2, graphite, PTFE, PA, PE, PI in lubricating lacquers or in pastes,

wax glazes, wax dispersions, greases, oils (as-delivered condition)

|

|

|

hot-dip galvanized |

MoS2, graphite, wax dispersions

|

|

|

organic coatings |

with integrated solid lubrication or wax dispersion |

|

|

austenitic steel |

solid lubricants or waxes; pastes

|

| C |

0.14–0.24 |

austenitic steel |

wax dispersions, pastes |

|

|

metallic, bright-polished

phosphated

|

as delivered state (lightly oiled) |

|

|

galvanic coatings such as Zn, Zn/Fe, Zn/Ni

non electrolytically applied zinc

adhesive

|

none |

| D |

0.20–0.35 |

austenitic steel

galvanic coatings such as Zn/Fe

hot-dip galvanized

|

oil

none

|

| E |

>= 0.30 |

galvanized coatings such as Zn/Fe, Zn/Ni

austenitic steel

Al and Mg alloys

|

none |

µG = coefficient of friction in the thread

µK = coefficient of friction in the head bearing area

µT = coefficient of friction at the interface